Ukubumba ukuvuthela, okwakwaziwa njengokubumba umngxuma wokuvuthela, yindlela yokulungisa iplastiki ephuhlayo ngokukhawuleza.Ngexesha leMfazwe yeSibini yeHlabathi, inkqubo yokubumba isivuthelo yaqala ukusetyenziswa ukuvelisa iingqayi ze-polyethylene ezixineneyo.Ngasekupheleni kweminyaka yee-1950, kunye nokuzalwa kwe-polyethylene ephezulu kunye nokuphuhliswa koomatshini bokubumba, iteknoloji yokubumba yayisetyenziswa ngokubanzi.Umthamo wezikhongozeli ezingenanto unokufikelela kumawaka eelitha, kwaye enye imveliso yamkela ulawulo lwekhompyutha.Iiplastiki ezifanelekileyo ukubumba ukuvuthela ziquka i-polyethylene, i-polyvinyl chloride, i-polypropylene, i-polyester, njl njl. Izikhongozelo ezingenanto ezibangelwayo zisetyenziswa ngokubanzi njengemigqomo yokupakisha yoshishino.Ngokwendlela yokuvelisa i-parison, ukubumba isivuthelo kunokwahlulwa ku-extrusion blow blowing kunye ne-injection blow blowing.Ezi zisanda kuphuhliswa zi-multi-layer blow blowing kunye ne-stretch blow blowing.

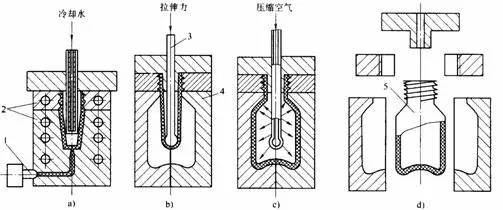

Isitofu solula vuthela ukubumba

Okwangoku, itekhnoloji yokubumba itekhnoloji yokufaka inaliti isetyenziswa kakhulu kunokubumba isitofu.Le ndlela yokubumba isivuthelo ikwayinaliti yokubumba, kodwa yongeza kuphela uxinzelelo lwe-axial, isenza ukubumba isivuthelo kube lula kunye nokunciphisa ukusetyenziswa kwamandla.Umthamo weemveliso ezinokucutshungulwa ngokutofa ngokutofa nokuvuthela mkhulu kunoko ngokuvuthela ngesitofu.Umthamo wesitya esinokuvuthelwa ngu-0.2-20L, kwaye inkqubo yayo yokusebenza imi ngolu hlobo lulandelayo:

1. Umgaqo wokubumba inaliti iyafana naleyo yokubumba isitofu esiqhelekileyo.

2. Emva koko ujike i-parison kwi-heater kunye nenkqubo yokulawula ubushushu ukwenza i-parison ithambile.

3. Jikela kwisikhululo sokutsala kwaye uvale i-mold.Intonga yokutyhala kumbindi yolula i-parison ecaleni kwendlela ye-axial, ngelixa ivuthela umoya ukwenza i-parison isondele eludongeni lokungunda kwaye ipholile.

4. Ukutshintshela kwisikhululo sokudilizwa ukuze uthathe iinxalenye

Qaphela - ukutsala - inkqubo yokuvuthela:

Isitofu sokubumba icawe → icawe yokufudumeza → ukuvala, ukuzoba nokuvuthela → ukupholisa nokuthatha iinxalenye

Umzobo weSchematic wesakhiwo somatshini wenaliti, umzobo kunye nokuvuthela

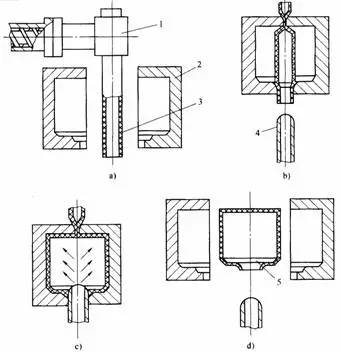

Extrusion blowulding

Ukubumba i-Extrusion blowhonye yeyona ndlela isetyenziswa kakhulu ekubumbeni ukuvuthela.Uluhlu lwalo lokucubungula lubanzi kakhulu, ukusuka kwiimveliso ezincinci ukuya kwizikhongozeli ezinkulu kunye neendawo zemoto, iimveliso zemichiza ye-aerospace, njl. Inkqubo yokucubungula ngolu hlobo lulandelayo:

1. Okokuqala, nyibilika kwaye udibanise i-rubber, kwaye inyibilika ingena kwintloko yomatshini ukuze ibe yi-parison ye-tubular.

2. Emva kokuba i-parison ifikelele kubude obumiselweyo, i-mold mold mold ivaliwe kwaye i-parison ifakwe phakathi kweziqingatha ezibini zobumba.

3. Vuthela umoya, vuthela umoya kwiparini, vuthela i-parison ukuyenza ibe kufutshane nomgodi wokubumba.

4. Iimveliso zokupholisa

5. Vula isikhunta kwaye uthathe iimveliso eziqinileyo.

Inkqubo yokubumba ukuvuthela:

Ukunyibilika → iparini ekhuphayo → ukuvala ukubumba kunye nokuvuthela ukubumba → ukuvulwa komngundo kunye nokuthatha inxalenye

Umzobo weSchematic of extrusion blow umgaqo wokubumba

(I-1 - intloko ye-extruder; i-2 - i-mold mold; i-3 - i-parison; i-4 - umbhobho wokuvuthela umoya; 5 - iinxalenye zeplastiki)

Isitofu sokuvuthela ukubumba

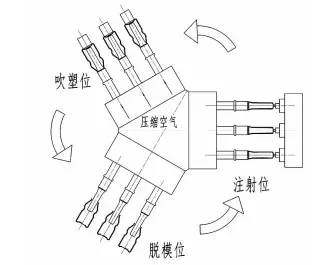

I-injection blow molding yindlela yokubumba edibanisa iimpawu zokubumba kunye nokuvuthela.Okwangoku, isetyenziswa ikakhulu kwiibhotile zokusela, iibhotile zamayeza kunye nezinye iindawo ezincinci zokuvuthela ngokuchaneka okuphezulu.

1. Kwisikhululo sokubumba i-injection, i-embryo ye-mold ifakwe kuqala, kwaye indlela yokucubungula iyafana naleyo yokubunjwa kwenaliti eqhelekileyo.

2. Emva kokuba isitofu sokungunda sivulwe, i-mandrel kunye ne-parison zifudukela kwisikhululo sokubumba.

3. I-mandrel ibeka i-parison phakathi kokubumba ukuvuthela kwaye ivale i-mold.Emva koko, umoya oxinanisiweyo uvuthelwa kwi-parison phakathi kwe-mandrel, kwaye emva koko uvuthelwe ukwenza ukuba kufutshane nodonga lokungunda kwaye lupholile.

4. Xa kuvulwe ngundo, mandrel idluliselwa kwisikhululo demoulding.Emva kokuba inxalenye yokubumba ivuthwe, i-mandrel idluliselwa kwisikhululo sokutofa ukuze sijikelezwe.

Inkqubo yokusebenza yokuvuthela inaliti:

Vuthela icawe yokubumba → ukuvulwa kwesitofu sokubumba kwisikhululo sokuvuthela ifilim → ukuvala ukubumba, ukuvuthela ukubumba kunye nokupholisa → ukujikeleziswa kwisikhululo sokudiliza ukuthatha iinxalenye → intolongo

Umzobo weSchematic womgaqo wokubumba isitofu sokuvuthela

Izinto eziluncedo kunye nezingeloncedo zokubumba isitofu sokuvuthela:

inzuzo

Imveliso inamandla amakhulu kunye nokuchaneka okuphezulu.Akukho kudibanisa kwisitya kwaye akukho mfuneko yokulungisa.Ukungafihli kunye nokugqitywa komphezulu weendawo ezibunjiweyo zokuvuthela zilungile.Isetyenziswa ikakhulu kwizikhongozeli zeplastiki eziqinileyo kunye nezikhongozeli zomlomo obanzi.

ukusilela

Iindleko zezixhobo zomatshini ziphezulu kakhulu, kwaye ukusetyenziswa kwamandla kukhulu.Ngokubanzi, kuphela izikhongozeli ezincinci (ngaphantsi kwe-500ml) ezinokuthi zenziwe.Kunzima ukwenza izikhongozeli ezinemilo enzima kunye neemveliso ze-elliptical.

Nokuba kukubumba ukuvuthela ngesitofu, ukubumba ukuvuthela ngokutofa, ukubumba ukubunjwa kwe-extrusion, kwahlulwe kwaba yinkqubo yexesha elinye kunye nenkqubo yokubumba kabini.Inkqubo yokubumba yexesha elinye ine-automation ephezulu, ukuchaneka okuphezulu kwe-parison clamping kunye ne-indexing system, kunye neendleko eziphezulu zezixhobo.Ngokubanzi, uninzi lwabavelisi basebenzisa indlela yokubumba kabini, oko kukuthi, ukubumba iprison kuqala ngokubumba inaliti okanye i-extrusion, kwaye emva koko bafake i-parison komnye umatshini (umatshini wokuvuthela ngesitofu okanye umatshini wokutsala inaliti) ukuvuthela imveliso egqityiweyo, ngokuphezulu. ukusebenza kakuhle kwemveliso.

Ixesha lokuposa: Mar-22-2023